Applied laser solutions

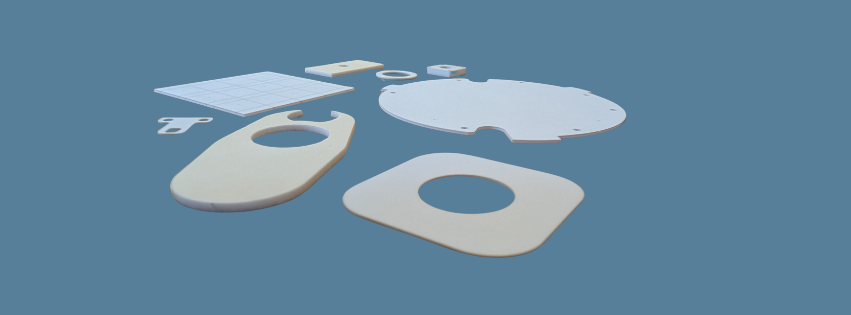

Celebrating 25 years in business, Applied Laser Solutions Ltd delivers precision laser-cut technical ceramics powered by cutting-edge machinery, process discipline and competitive pricing. We bring over 40 years of industry experience, so whether you need fast-track prototypes or dependable volume production, you get tight tolerances, quick turnarounds and consistent results.

Why work with us

ISO 9001 approved (current certificate available on request)

Worldwide distribution

Flexible pricing policy and low set-up/tooling charges

One-offs to volume production with fast-track prototypes

Full inspection including computer-controlled CMM

Post-definition work (secondary ops, refinements)

Capabilities

Laser cutting/scribing of alumina from 0.254 mm to 4.00 mm

Rapid prototypes through to production

Tight tolerances for thick-film, thin-film and engineering applications

Materials we process

Alumina 96% & 99% — thick/thin film & engineering grades

Specified grades — CoorsTek ADS-96R, CeramTec Rubalit 708S

Other technical materials — Aluminium Nitride, Zirconia, Quartz, Sapphire

Flexible substrates — FR-4, Mylar, Silicone Rubber, Acrylics

Please note that the materials we process are dependent on the required thickness

Sectors we serve

• Aerospace • Automotive • Defence • Energy • Engineering • Medical • Micro-electronics • • RF/Microwave • Semiconductor • Thick & Thin-film Hybrid Circuits •