Products

Substrates for Thick & Thin Film Applications

Laser scribed, drilled and profiled ceramic substrates for the micro-electronics, micro-hybrid, semiconductor, defence and aerospace industries.

Why laser? Most thick and thin film substrates are 96% alumina (Al₂O₃) which is extremely hard and not easily machinable so laser processing is the most efficient way to achieve clean features and tight repeatability.

Miniaturisation, one setup: Thick-film is a miniaturised process where a single substrate often carries many final circuits. With lasering, we scribe, profile, and drill in one setup:

Scribing: a line of laser pulses removes 30–50% of the material to create controlled break lines so panels snap cleanly into singles.

Drilling: produces vias between sides of the substrate.

Profiling: creates complex shapes in the ceramic.

Feature capability: Holes down to 0.06 mm are achievable (material-thickness dependent).

Common thicknesses: 96% alumina at 0.635 mm and 1.0 mm are typical; hybrid circuits are also produced from 0.254 mm up to 1.5 mm.

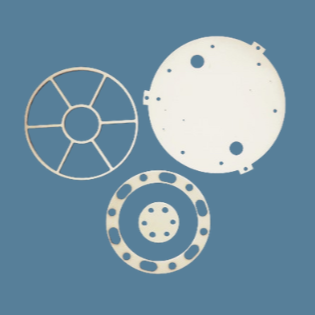

Laser-Cut Technical Ceramics for Engineering

Drilled and profiled parts for mechanical and engineering applications.

Design freedom: Laser cutting lets you design complex shapes with ease. 96% alumina is hard-wearing and heat absorbing, ideal for:

Wear parts

Thermal management

Electrical management

You’ll find ceramic components across automotive, defence, medical, and even everyday household products.

Cost-effective at any scale: Lasering is economical, there no tooling charges when you order from us, which makes one-offs and prototypes as viable as volume production.

Workable tolerances of ±0.05 mm apply in most thicknesses.

Thick material capability: We cut alumina up to 4 mm thick (stock up to 3 mm).

File formats: CAD/CAM drawings accepted in DXF.

Materials & Grades

Alumina 96% & 99% for thick/thin film and engineering applications

Specified grades: CoorsTek ADS-96R, CeramTec Rubalit 708S

Also process (thickness-dependent): Aluminium Nitride, Zirconia, Quartz, Sapphire

Flexible substrates: FR-4, Mylar, Silicone Rubber, Acrylics

At-a-Glance Specs

Scribe depth: 30–50% (for clean snap-outs)

Min hole size: as small as 0.06 mm (thickness-dependent)

Typical alumina thicknesses: 0.254–1.5 mm (common: 0.635 mm, 1.0 mm)

Max alumina thickness: 4.0 mm (stock to 3.0 mm)

Tolerances: ±0.05 mm (most thicknesses)

Turnaround: Quick—usually 5–7 working days

CAD: DXF accepted

Quality & Service

ISO 9001 (2000) approved

Worldwide distribution

No tooling charges & flexible pricing

One-offs to volume production

Fast-track prototypes

Full inspection, including computer-controlled CMM

Design consultation available

Summary

CoorsTek & CeramTec stockists

No tooling charges

±0.05 mm workable tolerances

Up to 4 mm alumina thickness

One-offs & prototypes economically viable

Complex shaping to fit any application

Quick turnaround (usually 5–7 working days)

Digital drawings accepted (DXF)